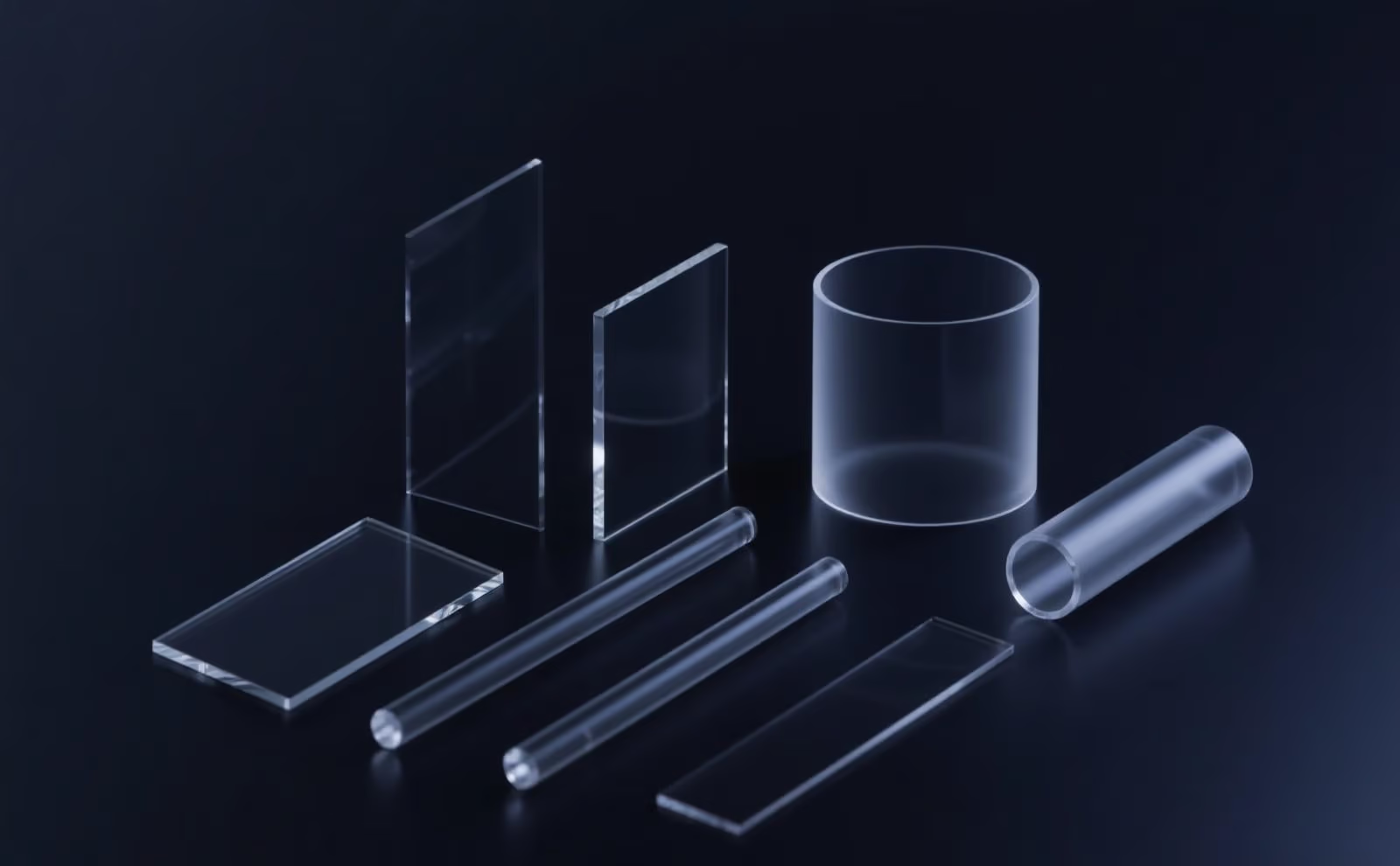

Quartz tubes can always be seen in precision instruments in laboratories, in core equipment for industrial production, and even in technological products in daily life. This transparent tube made of silicon dioxide as the main component seems ordinary, but with its unique physical and chemical properties, it has become an indispensable key component in many fields. Today, let us explore the diverse uses of quartz tubes and unveil its mysterious veil.

In the field of scientific research experiments, quartz tubes are a powerful assistant for researchers. Due to its high temperature resistance, it can withstand high temperatures of up to about 1700℃ and plays an irreplaceable role in high temperature experiments. For example, in materials science research, when scientists need to sinter or heat treat metal or ceramic materials at high temperatures, quartz tubes can provide a stable high temperature environment for samples, and they will not deform or melt due to high temperatures, ensuring the accuracy of the experiment. At the same time, the excellent chemical stability of quartz tubes makes it almost non-reactive with common chemical reagents such as acids and alkalis. When conducting complex chemical synthesis experiments, it can avoid interference with reactants and ensure the reliability of experimental results. In gas analysis experiments, quartz tubes are used as reaction vessels to accurately control the flow and reaction process of gases, helping researchers obtain accurate experimental data.

In industrial production, quartz tubes are also widely used. In the semiconductor manufacturing industry, quartz tubes are important consumables in the production process. Its high purity and good chemical stability can ensure that no impurities are introduced in process links such as high-temperature diffusion and oxidation, ensuring the performance and quality of semiconductor chips. In the field of optical fiber manufacturing, quartz tubes are core materials. Through complex processes, quartz tubes are made into optical fiber preforms, and then through the drawing process, optical fibers with fast transmission speed and low loss are produced, laying the foundation for the rapid development of modern communication networks. In addition, in the solar photovoltaic industry, quartz tubes are used to manufacture high-temperature equipment required for silicon wafer production, such as diffusion furnaces, annealing furnaces, etc., to help improve the conversion efficiency of solar cells.

In the field of lighting and optics, quartz tubes also shine. Since quartz tubes have good permeability to ultraviolet rays, visible light and infrared rays, they are often used to make special light sources. For example, in ultraviolet germicidal lamps, quartz tubes as lamp materials can allow ultraviolet rays to penetrate smoothly and achieve the function of efficient sterilization and disinfection. They are widely used in hospitals, food processing plants and other places. In high-intensity gas discharge lamps such as high-pressure mercury lamps and metal halide lamps, quartz tubes can not only withstand high temperature and high pressure working environments, but also ensure stable light output, providing powerful light source support for urban lighting, industrial lighting, etc. At the same time, quartz tubes are also used in optical instruments, such as as sample pools for spectrometers, using their good light transmittance to help instruments accurately analyze the spectral characteristics of substances.

Quartz tubes also play a role quietly in daily life and other fields. In some high-end kitchen appliances, such as quartz tube electric ovens, quartz tubes can quickly generate high temperatures and achieve uniform baking of food by taking advantage of their fast heating speed and high thermal efficiency. Quartz tubes are also common in laboratory heating equipment and teaching experimental equipment in colleges and universities, providing convenience for teaching and scientific research. In addition, in geological exploration, environmental monitoring and other fields, quartz tubes are also used for sample collection, preservation and analysis, helping professionals obtain accurate environmental and geological information.

From scientific research experiments to industrial production, from lighting optics to daily life, quartz tubes have demonstrated powerful functions in different fields with their excellent performance. With the continuous advancement of science and technology, I believe that quartz tubes will play a role in more new fields and bring more surprises to our lives and technological development.

If you need to purchase quartz tubes in large quantities, please contact us. We are good quality and low price.